PS inert

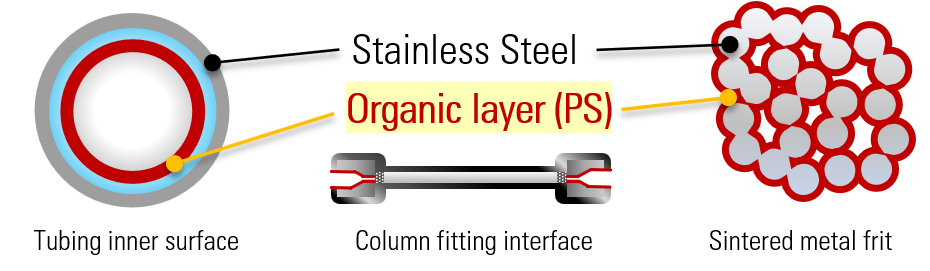

We offer the inert column hardware option, “PS inert,” which features a multilayer organic inert surface treatment applied to stainless steel components.

Unlike so-called stainless steel–PEEK double-tube metal-free columns, the hardware itself retains the robustness and mechanical strength of stainless steel.

PS inert provides excellent handling while maintaining metal-free performance, and it exhibits outstanding low-adsorption characteristics even when used with HPLC systems constructed with stainless steel tubing.

Reference: Highly inert end-capping and Novel inert column hardware [PDF]

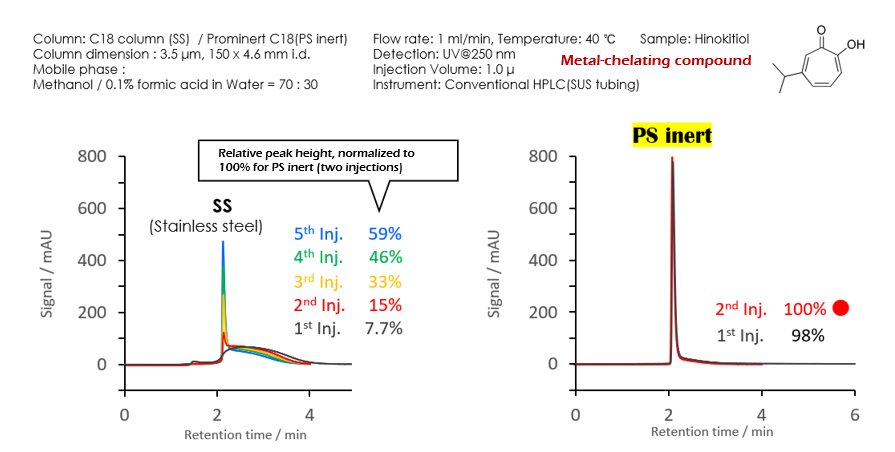

In HPLC, it is a known approach to improve the peak shape of metal-adsorptive compounds by passivating stainless steel surfaces using mobile phases containing chelating agents such as phosphate or EDTA, resulting in so-called “masked columns.” However, this approach is not recommended for MS applications due to the risk of ion source contamination.

PS inert achieves similarly excellent peak shapes to those obtained with masked columns even when using non-chelating mobile phases (e.g., 0.1% formic acid), and enables reproducible detection.

PS inert is therefore a useful solution for the low-level detection of adsorptive compounds in LC/MS applications.

The figure above shows a comparative analysis of a metal-chelating compound (hinokitiol) on PS inert and stainless steel (SS) columns under formic acid mobile phase conditions intended for LC/MS applications.

With the SS column, little or no peak was observed on the first injection, and the peak intensity gradually increased with successive injections. In contrast, PS inert provided high peak intensity from the very first injection.

It is also noteworthy that excellent reproducibility of peak intensity was achieved in a general-purpose HPLC system constructed with stainless steel tubing. This clearly demonstrates that the column, which has a much larger surface area, exerts a far greater influence as an adsorption site than the instrument itself.

PS inert is a metal-free column option that enables effective inertization while using existing LC/MS instrumentation without modification.

Material

PS (organically inert–treated stainless steel): all wetted parts, including the column connection interfaces, sintered metal frits, and the inner surfaces of the tubing

Compatible Packing Materials

All in-house packing materials, including SunBridge, Prominert, SunShell, Sunniest, and SunArmor

Column Dimensions

2.1 × 50 mm, 2.1 × 100 mm, 2.1 × 150 mm

Part Number Designation

“PS” is indicated at the end of the part number in place of the standard suffix “(1)” for each column model

Example:

SunBridge C18, 2.6 µm, 2.1 × 150 mm (Part No. CB6971) in the PS inert configuration

→ SunBridge C18, 2.6 µm, 2.1 × 150 mm, PS inert (Part No. CB697PS)